Phone Orders Accepted!

800.421.6265 | 323.268.8514

Meat Grinders

MPBS Industries located in Los Angeles CA 90023

Meat grinders are use to grind or mince meat to make sausages, hamburgers, meat balls, meat loaf, etc. They are also known as meat choppers and meat mincers. Meat grinders come in several different sizes (most grinder uses grinder plate sizes 12, 22, 32, 52, etc.) and can be used in various ways but in most restaurants, grocery stores and home use, the most common is the table top meat grinder.

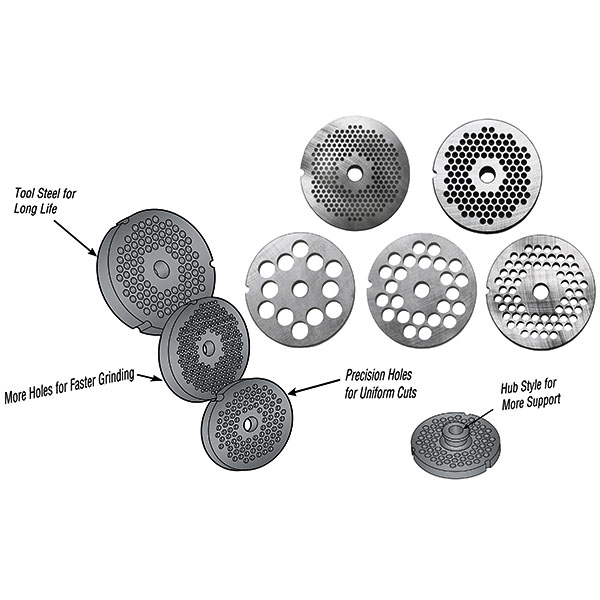

A meat grinder is a machine used to force meat or meat trimmings by means of a feeding worm (auger) under pressure through a horizontally mounted cylinder (barrel). At the end of the barrel there is a cutting system consisting of star-shaped knives rotating with the feeding worm and stationary perforated discs (grinding plates).

The perforations of the grinding plates normally range from 1 to 13mm. The meat is compressed by the rotating feeding auger, pushed through the cutting system and extrudes through the holes in the grinding plates after being cut by the revolving star knives. Simple equipment has only one star knife and grinder plate, but normally a series of plates and rotary knives is used. The degree of mincing is determined by the size of the holes in the last grinding plate. If frozen meat and meat rich in connective tissue is to be minced to small particles, it should be minced first through a coarse disc followed by a second operation to the desired size.

Two different types of cutting systems are available, the “Enterprise System” and the “Unger System”.

Some people use table top meat grinders to grind beef, pork, chicken, turkey and now fish. The tabletop meat grinders sold by MPBS Industries are commercial grade meat grinders used by professional, most are UL approved and NSF certified. MPBS Industries represents Butcher Boy table top meat grinders and German Knife Table Top Meat Grinder.

We also provide parts worldwide and local service in the Los Angeles and Southern California area for Butcher Boy grinders.

Please feel free to contact our professional sales and service staff to answer any questions you have on table top meat grinders. We also sell the accessories used with the grinders (ex. stainless steel dump buggies, storage bins, meat lugs, stainless steel trucks, etc.). The grinders should be cleaned after every use.

A meat grinder or meat mincer is equipment for fine chopping ('mincing') of, or mixing of raw or cooked meat, fish, vegetables or similar food. It replaces tools like the mincing knife, for example, which has been used to produce minced meat, filling etc. The producer puts the minced food into a funnel, which is placed on the top of the grinder. From there the material goes on a horizontal screw conveyor. This screw conveyor is powered by an electric motor, squashes and partially mixes the food. At the end of the screw conveyor there is a knife installed directly in front of the fixed hole plate. At this opening the minced meat comes out of the machine. The fineness of the meat depends on the size of the holes of the plate.

By changing the hole plate it is also possible to produce breadcrumbs or fill sausage casing. After the drop from the retainer, it is possible to change the hole plate. By removing the fixing screw the grinder can be disassembled completely for cleaning. Besides the domestic manually or motor operated grinders, there are also grinders for butchery (table- or shop-grinders for example) and for the food industry. Some large machines are able to produce several tons per hour.

Meat grinders are use to grind or mince meat to make sausages, hamburgers, meat balls, meat loaf, etc. They are also known as meat choppers and meat mincers. Meat grinders come in several different sizes (most grinder uses grinder plate sizes 12, 22, 32, 52, etc.) and can be used in various ways but in most restaurants, grocery stores and home use, the most common is the table top meat grinder.

A meat grinder is a machine used to force meat or meat trimmings by means of a feeding worm (auger) under pressure through a horizontally mounted cylinder (barrel). At the end of the barrel there is a cutting system consisting of star-shaped knives rotating with the feeding worm and stationary perforated discs (grinding plates).

The perforations of the grinding plates normally range from 1 to 13mm. The meat is compressed by the rotating feeding auger, pushed through the cutting system and extrudes through the holes in the grinding plates after being cut by the revolving star knives. Simple equipment has only one star knife and grinder plate, but normally a series of plates and rotary knives is used. The degree of mincing is determined by the size of the holes in the last grinding plate. If frozen meat and meat rich in connective tissue is to be minced to small particles, it should be minced first through a coarse disc followed by a second operation to the desired size.

Two different types of cutting systems are available, the “Enterprise System” and the “Unger System”.

Some people use table top meat grinders to grind beef, pork, chicken, turkey and now fish. The tabletop meat grinders sold by MPBS Industries are commercial grade meat grinders used by professional, most are UL approved and NSF certified. MPBS Industries represents Butcher Boy table top meat grinders and German Knife Table Top Meat Grinder.

We also provide parts worldwide and local service in the Los Angeles and Southern California area for Butcher Boy grinders.

Please feel free to contact our professional sales and service staff to answer any questions you have on table top meat grinders. We also sell the accessories used with the grinders (ex. stainless steel dump buggies, storage bins, meat lugs, stainless steel trucks, etc.). The grinders should be cleaned after every use.

A meat grinder or meat mincer is equipment for fine chopping ('mincing') of, or mixing of raw or cooked meat, fish, vegetables or similar food. It replaces tools like the mincing knife, for example, which has been used to produce minced meat, filling etc. The producer puts the minced food into a funnel, which is placed on the top of the grinder. From there the material goes on a horizontal screw conveyor. This screw conveyor is powered by an electric motor, squashes and partially mixes the food. At the end of the screw conveyor there is a knife installed directly in front of the fixed hole plate. At this opening the minced meat comes out of the machine. The fineness of the meat depends on the size of the holes of the plate.

By changing the hole plate it is also possible to produce breadcrumbs or fill sausage casing. After the drop from the retainer, it is possible to change the hole plate. By removing the fixing screw the grinder can be disassembled completely for cleaning. Besides the domestic manually or motor operated grinders, there are also grinders for butchery (table- or shop-grinders for example) and for the food industry. Some large machines are able to produce several tons per hour.