Phone Orders Accepted!

800.421.6265 | 323.268.8514

MPBS Industries1000 Marinating Vacuum Tumbler

MPBS Industries1000 Marinating Vacuum Tumbler

Catalog No.: 0007

Description

Features:Stainless steel construction

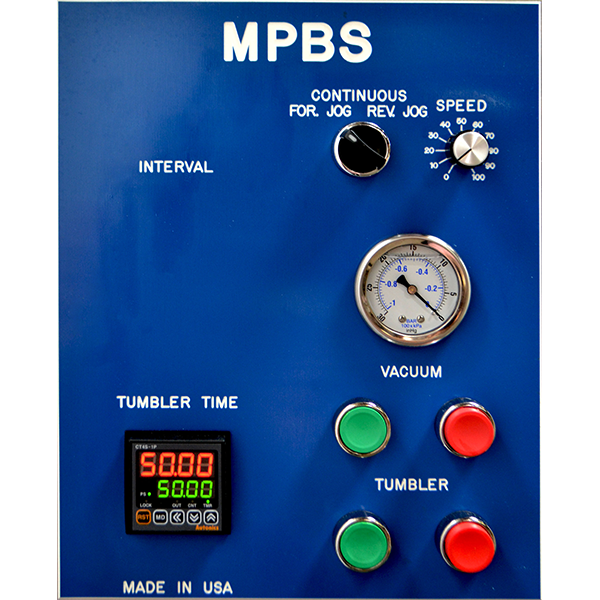

Forward mixing

Analog control

Vacuum gauge

O/A dims.: 76 L x 31 W x 49” H (63” H with optional Extension)

2 Safety sensors

USDA approved

Tub truck size capacity: +/- 55” L x 30” H (with optional Extension)

Flights: 5½” (2x)

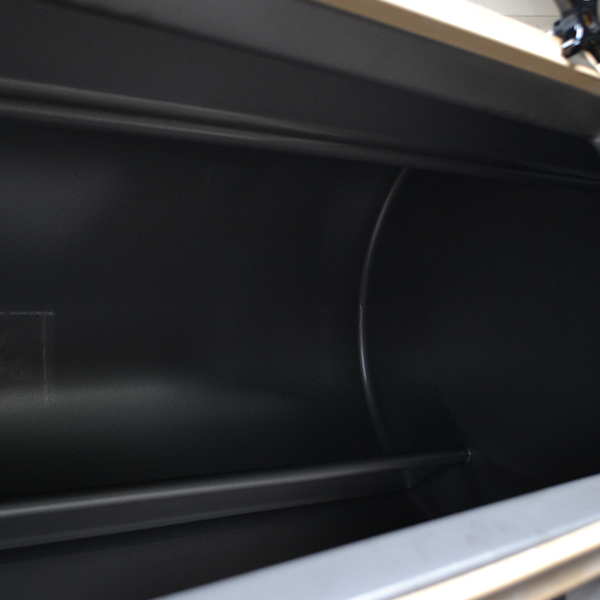

Drum:

Speed: 1 – 9 RPM

Size: 57½ x 30” D

Inside dims.: 53 x 29” D

Load capacity: Up to 1000 lb

Product opening: 23 x 13”

Heavy duty gasket

Digital timer

Standard Timer: 99 Hour 59 Minutes

Electrical: 110V / 60 Hz / 1 Ø

Chain motor

Variable speed motor: 11 amps

Vacuum pump: 20m³h

Vacuum pump and motor inside the cabinet

Made in the USA

Options:

Electrical

Intermittent timer

Stainless steel tub truck

Height Extension

Customized tub size: 45 L x 31 W x 27” H

Massage tumblers are used by meat processors throughout the world to add value to their product, and to produce a more desirable product for consumers. Tumbling meats can add flavor, water, and cure to the product. Tumbling also make the product tender.

Massage tumbling, is applying a mechanical process to a product over a length of time. The goal of massage tumbling is to bring salt soluble proteins to the surface of the product without damaging the tissue. The salt soluble protein, once it has been brought to the surface, can absorb water into the product, as well as help to dissolve seasoning for a better tasting product. The actual mechanical force applied to the meat can also help make the product more tender, as well as give the product a more uniform appearance.

Here are some of the immediate benefits to the processor:

1. Even distribution of cure and seasoning

2. Consistent salt levels throughout the product

3. Reduced labor cost over soaking and rubbing method

4. Reduced cure cost-No brine is being dumped down the drain

5. Reduced sawdust cost-Product takes smoke better

6. Free up extra cooler space by reducing marinating and soaking time

7. Energy savings from reduced cooling and smoking time

8. Reduced inventory

9. Faster inventory turnover

10. Reduced product cost

11. Reduced shrinkage

12. Improved cost control

13. Added value to the product

14. Overall improved quality of products

Customers are sure to notice these changes in your product:

1. More tender product

2. More moist product

3. Enhanced flavor from less purge and less cooking loss

4. Fresher taste

5. Improved appearance (more consistent color)

6. Even salt levels throughout the product