Phone Orders Accepted!

800.421.6265 | 323.268.8514

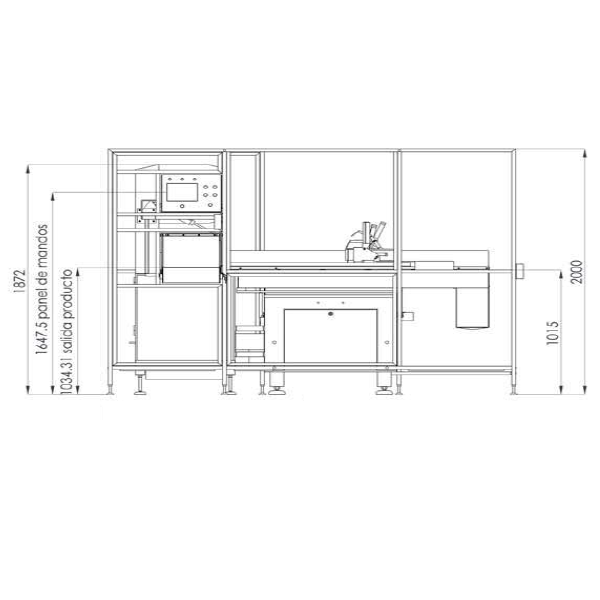

Pro-SawPS80AB Automated Meat Bandsaw

Pro-SawPS80AB Automated Meat Bandsaw

Catalog No.: 2324

Description

Features:Stainless steel construction (304L)

Right or left hand

Special safety features include the stainless steel safety cage and sensors to avoid any risk to the operator

Thickness and cutting speed are controlled electronically

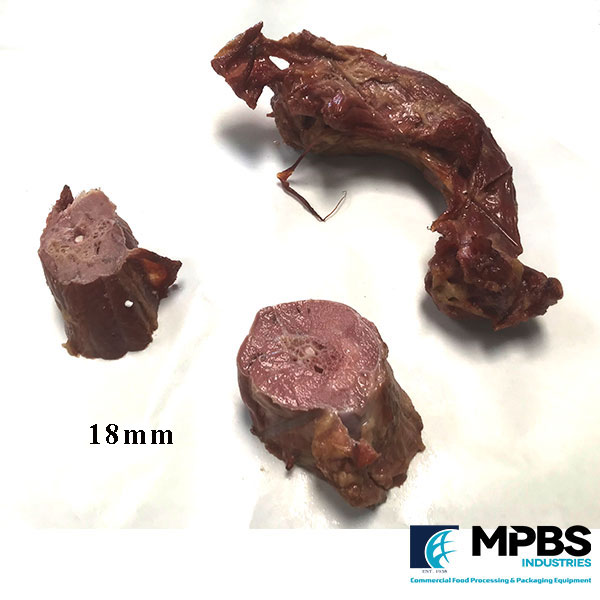

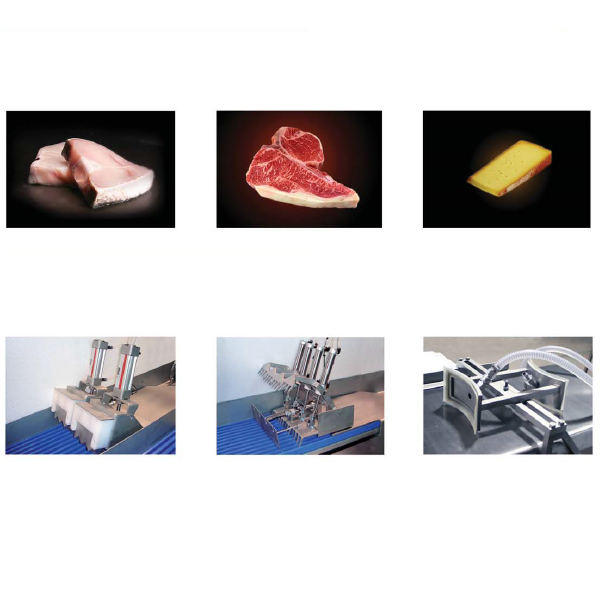

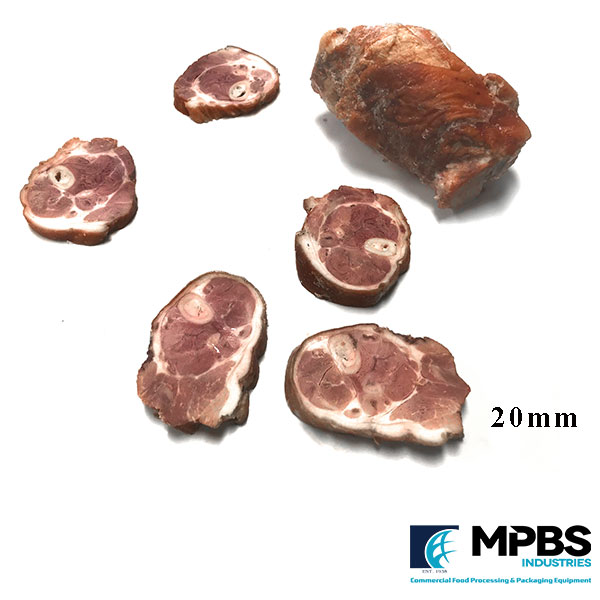

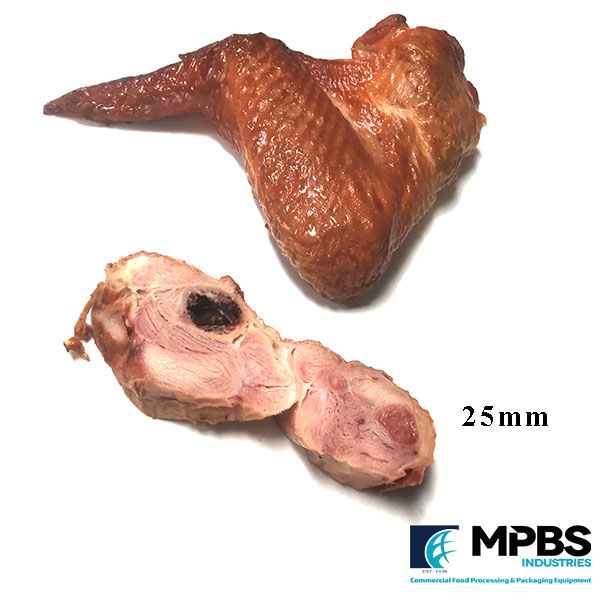

The automatic band saw was designed to automatically cut product pieces (dry meat, frozen meat and frozen fish) to an accurate consistent thickness.

When product measurements and cutting speed are decided, the operator needs to load the data into touch screen panel and push the start button to begin operation.

Schneider digital control panel

Emergency stop button

Tension, safety, and thermic indicator light

Restart button

On/Off saw button

On/Off cycle button

On/Off Lockout/tagout switch

Compressed air: 120 PSI (Provided by customer)

Adjustable legs for precise leveling

Interlock conveyor belt

Loading area

Blade speed: 14,500 FPM

Max height to be cut: +/- 13"

Minimum thickness: 1mm

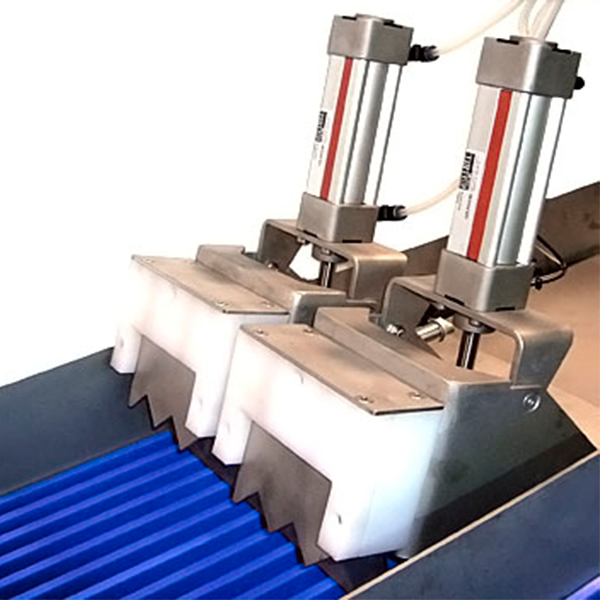

Product is held by specially designed pneumatic grippers

Includes 2 set of grippers per machine

Capacity: Up to 80 cuts/minute (depending on product)

Type of cuts:

Fixed cuts

Variable cuts

Heavy duty, 4 HP TEFC motor

Electrical: 220V / 60 Hz / 3 Ø, 13 amps

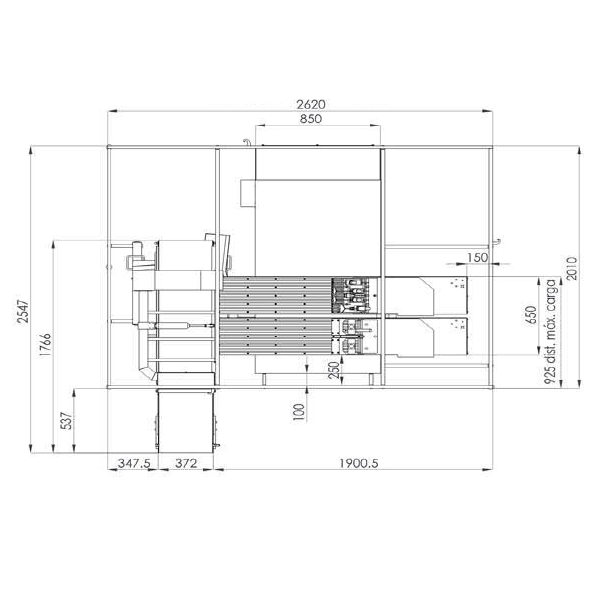

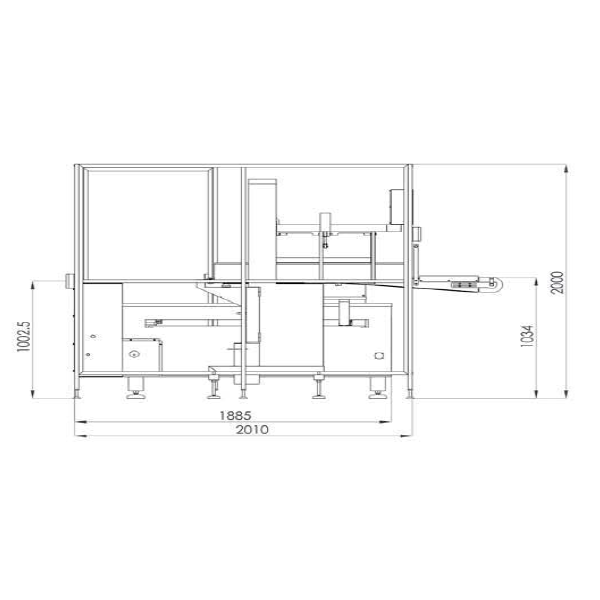

O/A dims.: +/- 116 L x 107 W x 75” H

100% stainless steel wheels (+/- 16” wheels)

Bandsaw Blade dims.: 5/8 x 125" x .018 - .025 thickness, 3 or 4 TPI

100% Washdown

Easy to clean and maintain

Removable conveyor belt for easy cleaning

Removable wheel and blade cleaner system

Disassemble main components easily without tools

Magnetic safety switches on the saw and around the cage

Use best with 400 or 600 lbs stainless steel buggies

Options:

Electrical: 440V / 60 Hz / 3 Ø

Smaller size cage

Additional gripper set (up to 2 per machine)

Different gripper (cheese, bones, and fish)

.jpg)